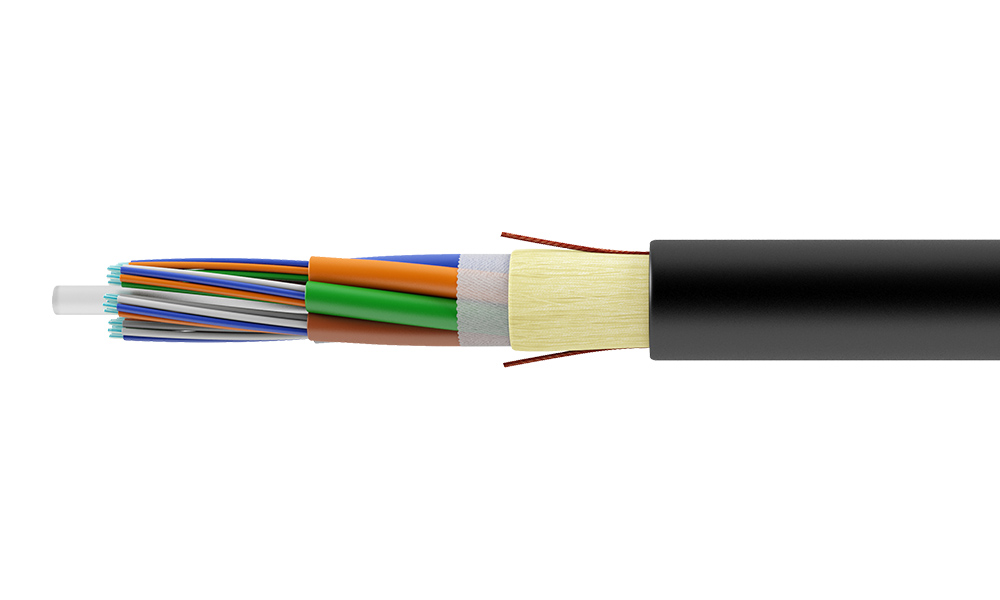

24F – 144F Loose Tube ADSS Optic Cable Corning Fiber | All-dielectric Aerial Fiber Optic Cable 80- 100M Span

Product Description

1 Introduction

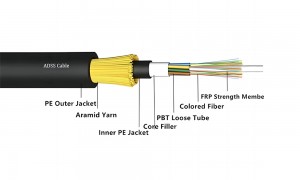

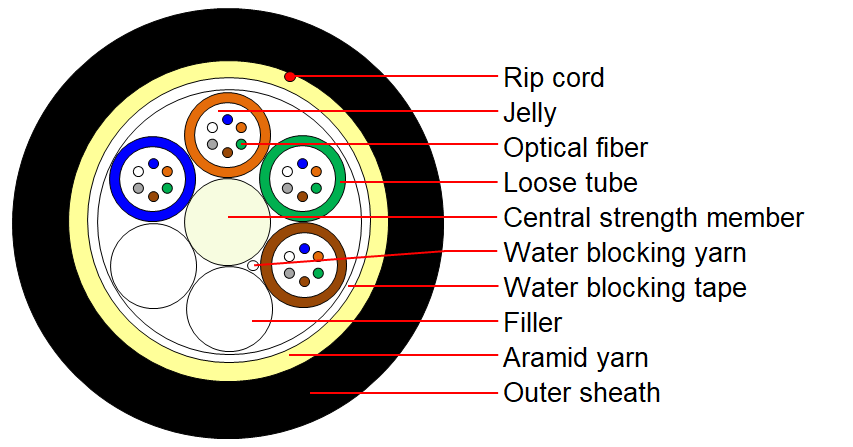

Loose tube construction, tubes jelly filled, elements (tubes and fillers when necessary) laid up around non-metallic central strength member, polyester yarns used to bind the cable core, water blocking tape wrapped the cable core, aramid yarns reinforced, 1 ripcord and PE outer sheath.

2. Characteristics of Optical Fiber

G652D fiber information

Mode field diameter (1310nm): 9.2mm±0.4mm

Mode field diameter (1550nm): 10.4mm±0.8mm

The cut-off wavelength of cabled fiber (lcc): £1260nm

Attenuation at 1310nm: £0.36dB/km

Attenuation at 1550nm: £0.22dB/km

Bending loss at 1550nm (100 turns, 30mm radius): £0.05dB

Dispersion in the range 1288 to 1339nm: £3.5ps/ (nm•km)

Dispersion at 1550nm: £18ps/ (nm•km)

Dispersion slope at zero dispersion wavelength: £0.092ps/ (nm2•km)

3. Fiber Color Code

Fiber color in each tube starts from No. 1 Blue.

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

|

Blue |

Orange |

Green |

Brown |

Gray |

White |

Red |

Black |

Yellow |

Purple |

Pink |

Aqua |

4. Color codes for loose tube & filler rod

Tube color starts from No. 1 Blue. If there are fillers, the color is nature.

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

|

Blue |

Orange |

Green |

Brown |

Gray |

White |

Red |

Black |

Yellow |

Purple |

Pink |

Aqua |

5. Cable structure and parameter

|

SN |

Item |

Unit |

Value |

||

|

1 |

No. of fibers |

count |

12/24 |

36 |

48 |

|

2 |

No. of fibers per tube |

count |

4 |

6 |

12 |

|

3 |

No. of elements |

count |

6 |

6 |

6 |

|

4 |

Tube diameter |

mm |

2.6 |

2.6 |

2.8 |

|

5 |

FRP diameter |

mm |

2.8 |

2.8 |

3 |

|

6 |

Inner sheath thickness |

mm |

0.8 |

0.8 |

0.8 |

|

7 |

Outer sheath thickness |

mm |

1.7 |

1.7 |

1.7 |

|

8 |

Cable diameter |

mm |

13.2 |

13.2 |

13.9 |

|

9 |

Cable weight |

kg/km |

144 |

147 |

158 |

|

10 |

MAT (Max. Allowable Working tension) |

N |

3600 |

3600 |

4000 |

|

11 |

Short term crush |

N/100mm |

2200 |

||

|

12 |

Max Span |

m |

100 |

||

|

13 |

Ice thickness |

mm |

0 |

||

|

14 |

Wind speed |

Km/h |

20 |

||

6. Characteristic of Optical Cable

6.1 Min. bending radius for installation

Static: 10 x cable diameter

Dynamic: 20 x cable diameter

6.2 Application temperature range

Operation: -20℃ ~ +70℃

Installation: -10℃ ~ +60℃

Storage/transportation: -20℃ ~ +70℃

6.3 Main mechanical & environmental performance test

|

Item |

Test Method |

Acceptance Condition |

| Tensile StrengthIEC 60794-1-2-E1 | - Load: Max. Allowable Working tension- Length of cable: about 50m- Load time: 1min | - Fiber strain £ 0.33%- No fiber break and no sheath damage. |

| Crush TestIEC 60794-1-2-E3 | - Load: Short term crush- Load time: 1min | - Loss change £ 0.1dB@1550nm- No fiber break and no sheath damage. |

Loose Tube ADSS Fiber Optic Cable Data Sheet.pdf